Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

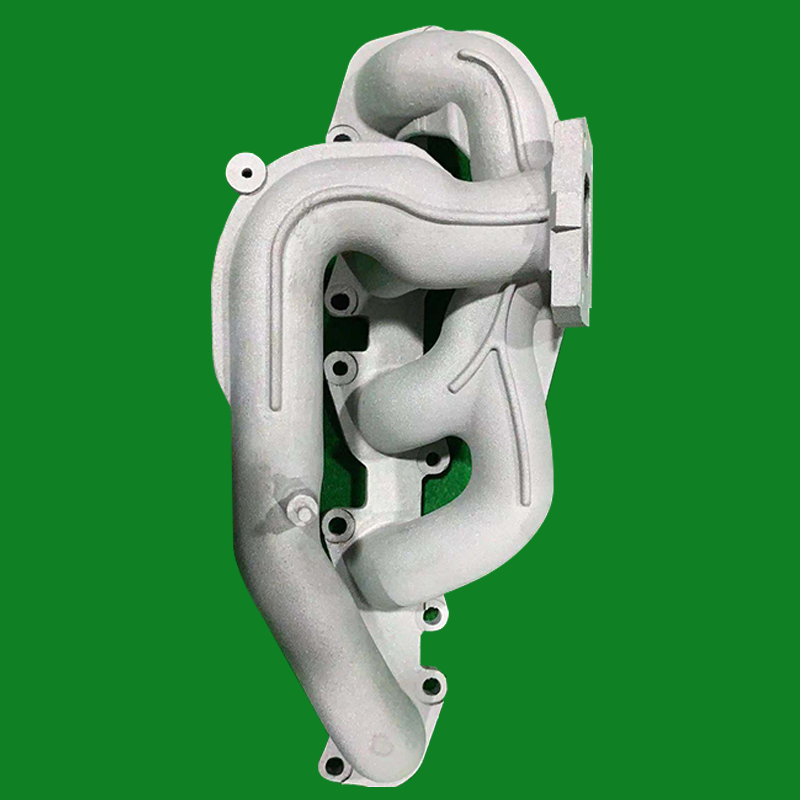

SLS 3D Printing

Selective Laser Sintering or SLS is an industrial 3D printing technology. It builds accurate and durable parts from nylon (PA 12) materials one layer at a time. The combination of low cost per part, established materials and its speed makes SLS a go-to solution among engineers for functional prototypes and low volume production parts.

SLS 3D printing is a mature, stable and repeatable process which can replace conventional manufacturing methods to produce parts.Using SLS technology, a high-powered laser selectively fuses powdered materials, typically polymers or metals, layer by layer to create a three-dimensional object. This additive manufacturing process allows for the production of complex geometries and intricate designs that may be challenging or impossible to achieve with traditional manufacturing techniques.

Specification

|

Our Capabilities |

Industrial SLS |

|

Maximum build size |

400 x 400 x 450 mm (15.7″ x 15.7″ x 17.7″) |

|

Lead time |

2-3 days |

|

Resolution |

± 0.2mm |

|

Prototyping Applications |

Functional and high-fidelity prototypes |

|

End-use applications |

Low volume functional end-use parts |

SLS 3D Printing Materials

|

|

Photo |

Description |

Material Reference |

Appearance |

|

TPU |

|

With SLS, you can 3D print TPU or rubber-like parts. It is very elastic, flexible, and smooth to the touch, but at the same time, extremely durable and strong. It is widely used in the automotive, medical and consumer goods industries. |

|

Many colors |

|

PA12+GF |

|

When filled with glass fibers (GF), SLS printed nylon can be a good alternative to metal. PA+GF offers the same advantages as polyamide but with much higher thermal resistance (up to 110°C), strength and rigidity. As such, it is ideal for demanding conditions where toughess, temperature performance or wear resistance is key. |

FS3300GF |

Whitish brown |

|

PA12 |

|

PA or nylon material have high wear resistance, high thermal stability and are exceptionally strong. For these reasons, SLS-printed nylon parts are popular among engineers across many sectors |

FS3300PA |

Black, White, Beige |

Typical SLS Finishing Options

|

|

Applicable Materials |

Colors |

Description |

|

Media Tumbling |

All |

/ |

Media tumbling, also known as vibro-polishing, is a process used to smooth the surface of SLS 3D printed parts. |

|

Dyeing |

All |

Black, Pantone/ RAL colours |

Dyeing is the fastest and most cost-effective way to colour SLS parts. It is mainly used to improve aesthetics. |

The Advantage of product

- Strong Functional Parts

Industrial SLS is an excellent choice for creating strong and durable parts with great accuracy. It can build parts for some of the most demanding applications.

- No Support Required

The use of powder bed fusion means there is no support material required. This makes SLS capable of producing geometries that no other technology can.

- Rapid Turnaround

SLS produces rapid prototypes and functional parts in as fast as 2 days, which allows parts to be tested much faster than via traditional methods.

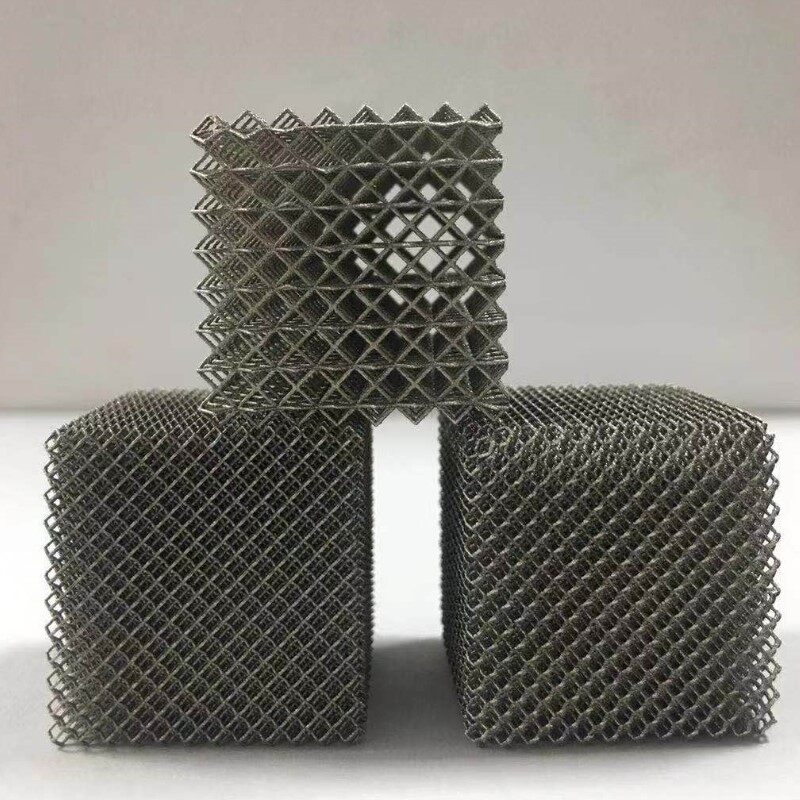

The Feature of product

- Unlike other 3D printing process, with selective laser sintering, you can stack multiple prints both horizontally and vertically, through the x, y, and z axes. This makes it an excellent choice for low-volume production.

- SLS does not require support structures, allowing for greater design freedom. To take full advantage of this technology, it is important that you design for the process. Learn actionable design tips here.

The Production Process of product

Selective laser sintering is a powder bed fusion (PBF) technology that uses a high-powered laser to sinter powdered material, binding it together to create a solid structure. Due to the surrounding powder, SLS can realise overhangs and complex features without support structures.